Overview

In this new version of my RC Car, the goals are to include the following new features in my car:

- A modular body

- All Wheel Drive (AWD)

- Suspension on all wheels

- Make it more durable overall

I am keeping the features from the previous car that worked while adding on to it to make a more rugged car.

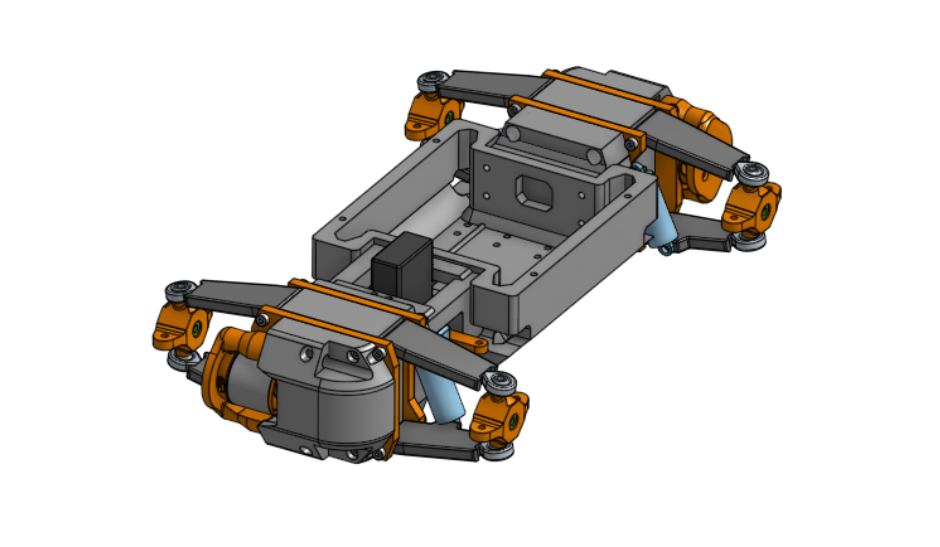

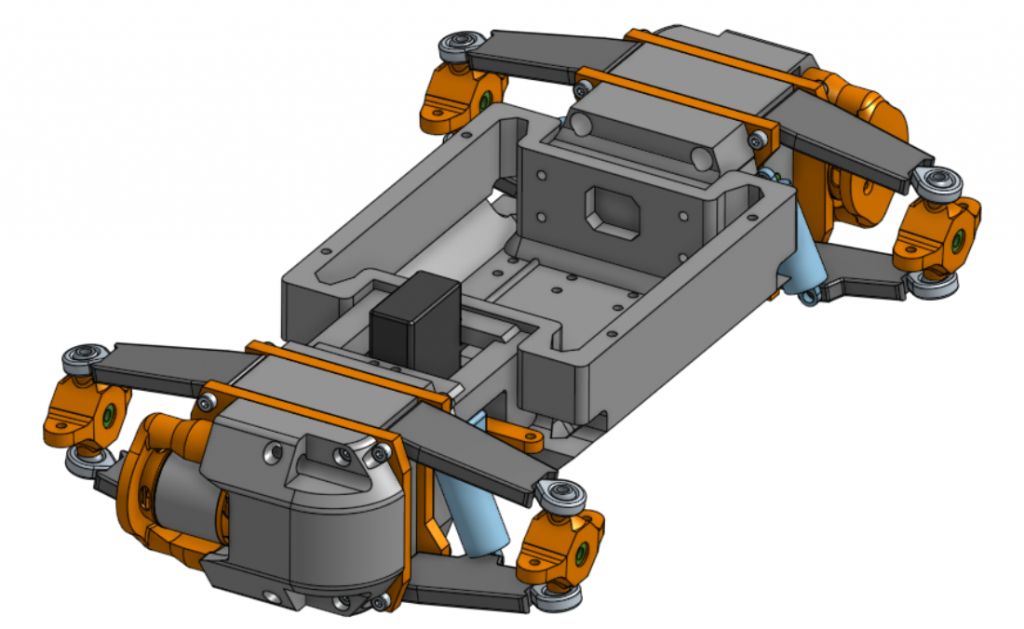

Main Body Design

(using RC Car (Version 1) as a reference)

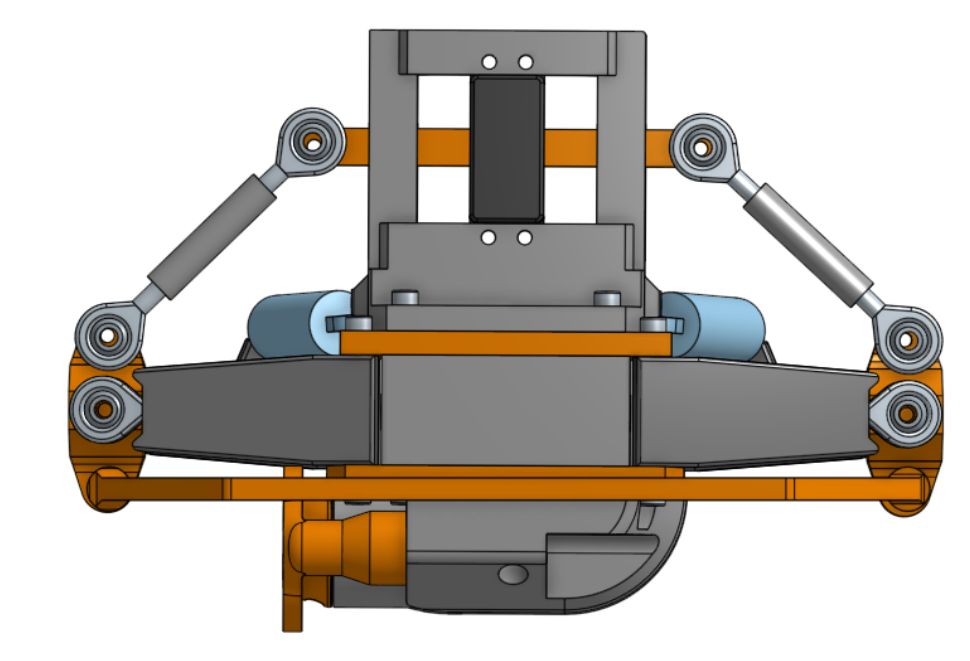

- Steering Section:

- The previous version’s steering system utilized a high torque servo and it worked flawlessly, I decided to use the same system for this new design.

- Due to the positioning of certain parts within this car, I positioned the servo closer towards the center of the car in order to fit the gear reduction and motor. This caused me to move the bars that connect the servo to the wheel.

- In the front of the steering system, I added a tie rod; in the previous model, the tie rod was able to go straight across the car due to the steering knuckles extending far past the car’s body. In this model, however, that would prove to be cumbersome, so I made the tie rod extend upwards and over the car.

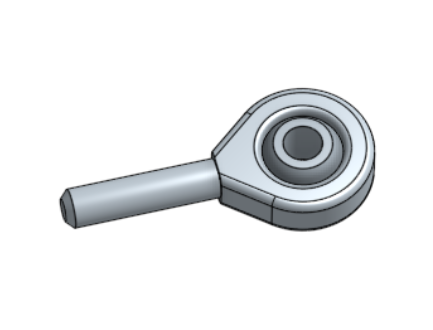

<=== (Heim Joints)

<=== (Heim Joints)- In the back of the steering system, I added a bar (steering bar) to the servo that was held in place by the servo horn and 2 blocks that attach to the frame. These blocks ensure that the steering bar remain horizontal even as the servo rotates in a circular fashion because if the steering bar were to rotate, the joints were unable to pull the tires properly (more on this in another section). The steering bar attaches to the wheel hubs via a set of rods with Heim Joints that allow the steering to work even if the steering bar is not perfectly aligned with the wheel hubs.

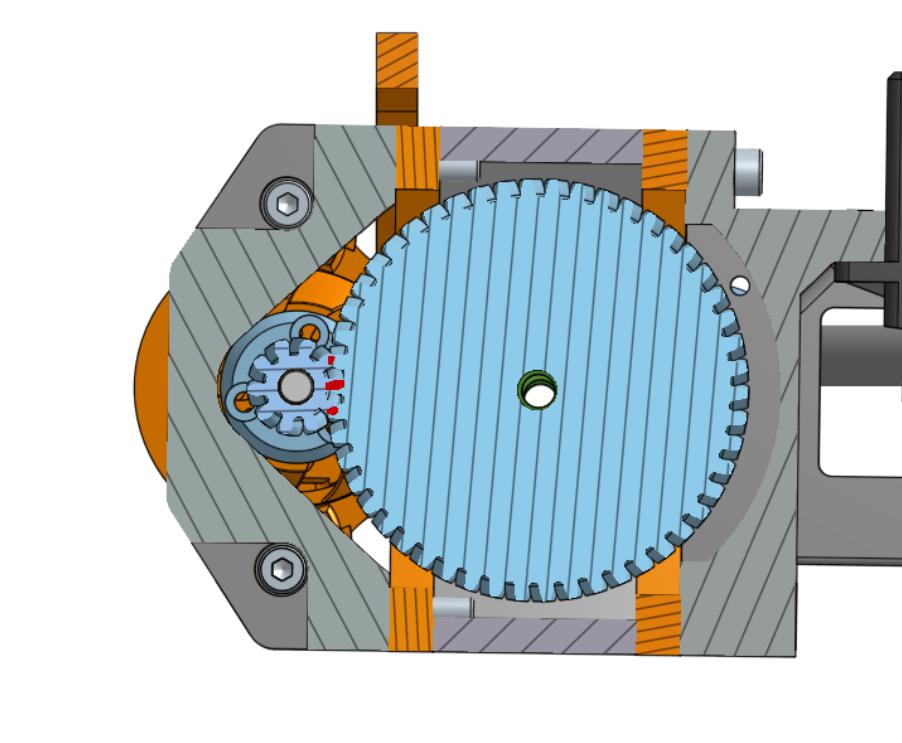

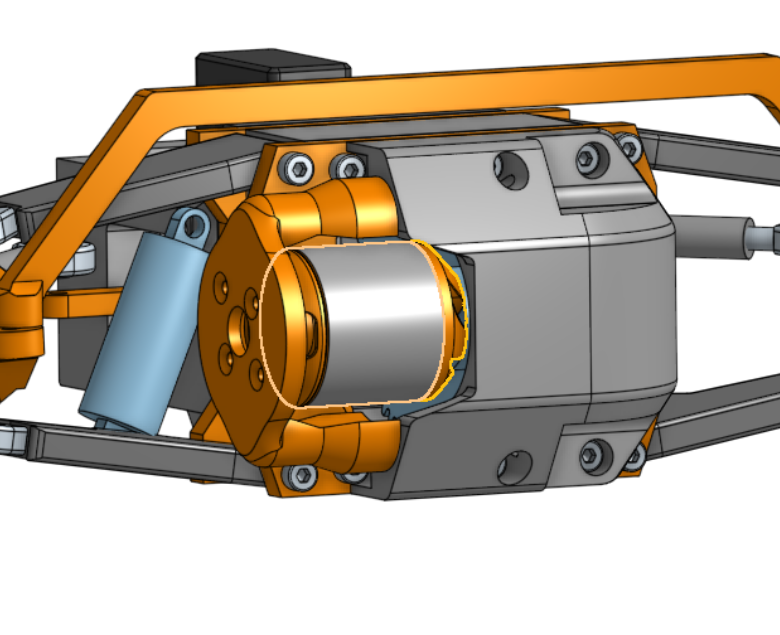

- Motor Housing

- In this version, I kept the same motors as in the previous one: FLASH HOBBY D3548 790kv BLDC Motors

- The previous motor was powered by a 40A ESC and had a 4:1 gear reduction. This proved to be very ineffective in providing torque to the car and caused it to accelerate extremely slowly. In this model, I used an 80A ESC with a 5:1 gear reduction. Since I increased the gear reduction and the ESC current-rating (the torque of a BLDC is proportional to the amount of current supplied), the motors were able to effortlessly push the car forward with very strong acceleration.

- In the previous design the motor housing was overly exposed and poorly secured to the car’s frame. This design changes that by adding a layer of to cover up the front of the motor (the part that has holes from which rocks/sediment can breach into the coils) and has many secure attachment points to mount the motor to the front and rear of the car.

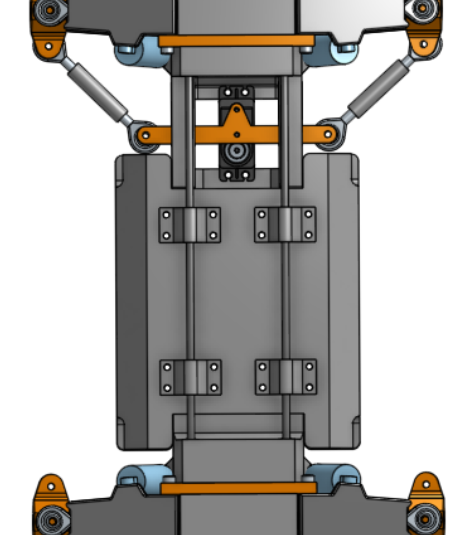

- Carriage Section:

- The carriage was designed to be much bigger than the one from the previous version in order to store the electronic components neatly.

- I also added a 4mm, stainless-steel rod to extend throughout the entire carriage and part of the front/rear modules which would help in supporting the car.

- These bars also allowed the car to traverse over bumps better since previously, the weak-points were where the front and rear modules attached to the carriage.

Things to Improve

- Steering:

- Currently, the steering tends to destabilize at higher speeds due to increased vibrations and this causes the steering to misalign and the car to drift.

- This is manageable at low throttles (10-30%) but as you increase speed, this tends to get extremely difficult to keep up with and the car may skid or veer off course

- The car tends to drift/veer to the right most of the time. I am still unsure of why this occurs, but I believe it may be due to a misalignment in the tie rods or the wheel hubs.

- Another issue in this is from the vibrations that occur in high speeds. What tends to occur is the vibrations shake the tie rods greatly as well as the steering bar that connects directly to the servo horn. These parts are not made to take the types of vibrations that occur and there have been issues parts cracking and fracturing.

- Suspension

- In my car, I was hoping to have a much more rugged suspension design that would allow it to travel in grass or rocky terrains. The coil-over suspension I used was not strong enough to carry the car properly and the car remained low to the ground. This is nice for a drift-style car, but that was not the intended purpose.

- If I were to keep the same coil-over springs, I might try to lower the position of the spring relative to the rest of the car so it would be able to hold the car up nicer.

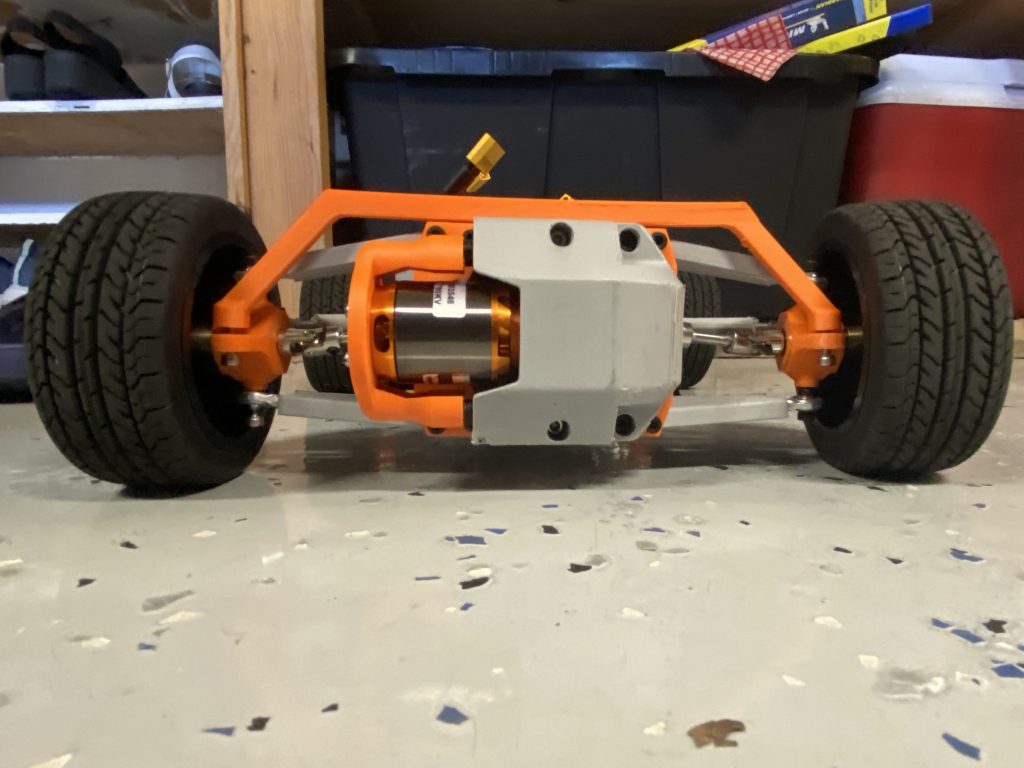

Photos/Videos: